Products

YC—Special System

Designed for manufacturing shoe sole and insole

YF – YL Product Systems

Designed for manufacturing shoe sole and insole

YM & YV Product systems

PU systems for manufacturing of car seat, motorbike saddle, mattress, pillow

YC – YR Product Systems

These systems are specifically designed for manufacturing high-performance flooring, utility poles, traffic light poles, and gas tanks.

Ecomate

Ecomate® blowing agent technology was born from the innovation of the Foam Supplies Chemistry Department. The advent of ecomate® technology and its evolution has become yet another benchmark in Foam Supplies’s history of formulating superiority and proves once again Success Through Innovation

Single-component rosewood adhesive

Mainly used for bonding various types of rosewood, it is an ideal glue for splicing rosewood and other hardwoods.

Polyurethane (PU) Compound Material - Soft Foam

Polyurethane flexible foam refers to soft polyurethane foam plastic, which is a soft polyurethane foam material with a certain degree of elasticity. It is the most widely used type of polyurethane product.

Polyurethane (PU) compound_material_elastomer

Cast polyurethane elastomer (abbreviated as CPU) is the most widely used and highest-yield type of polyurethane elastomer.

Polyurethane (PU) compound material - semi-rigid foam

Energy-absorbing foam — Energy-absorbing foam has excellent shock absorption and cushioning properties, good compressive load resistance, and deformation recovery performance. Its most typical application is in the production of car bumpers.

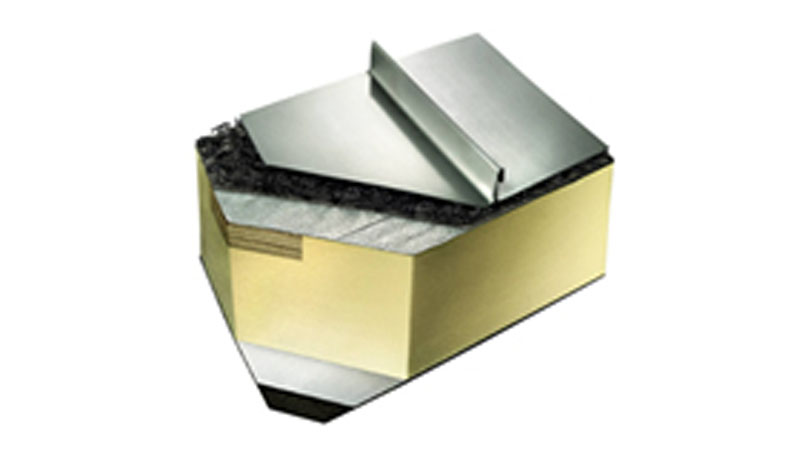

Polyurethane (PU) Compound_Hard Foam

Refrigeration and freezing equipment — such as refrigerators, freezers, cold storage rooms, and refrigerated trucks — polyurethane rigid foam is the most ideal insulation material for refrigeration and freezing equipment.

Packaging materials

It completely avoids the use of CFCs or HCFCs, harmful metals, or other banned substances. It is reusable and recyclable, complies with all national regulations in global certifications, and the company has developed a series of PU composite material formulas to ensure cost-effective solutions for your various packaging needs.

Slow-Rebound Composite Material

The advantages of slow-rebound products are: they have excellent viscoelastic properties (slow-rebound effect), a soft feel, and are mainly used in bedding and similar items.