Designed for manufacturing shoe sole and insole

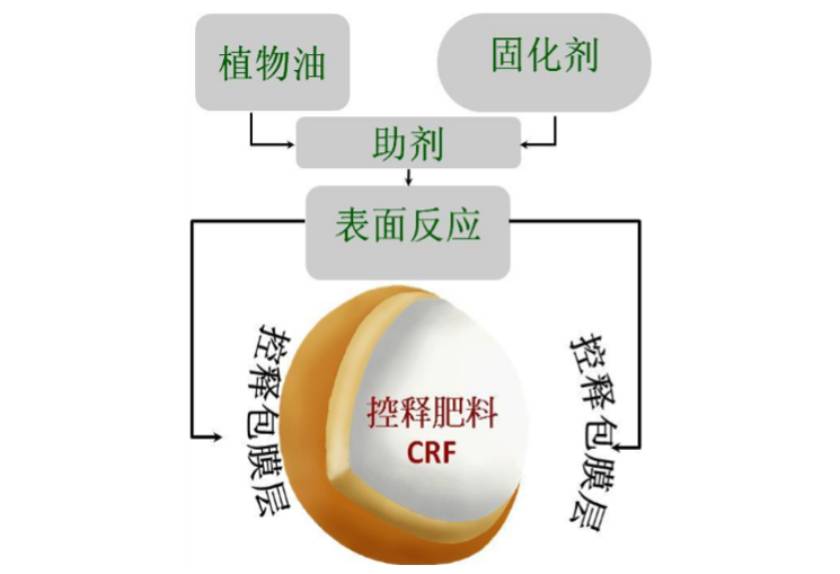

The YC 1266M78/10/2 system typically feeds the material in three stages. After the fertilizer undergoes surface pre-treatment, it enters the coating equipment. After pre-surface treatment, the fertilizer is heated to 55-65°C, and one-third of the polyol is added to the coating equipment. The fertilizer is mixed with the polyol for about 1-2 minutes, then isocyanate is added in the appropriate proportion, and mixing continues for 2-5 minutes to complete the reaction between the polyol and isocyanate. This feeding step is repeated twice, and the mixture in the container is further mixed for more than 20 minutes for post-curing. Finally, the material is cooled, and the finished product is discharged into bags.