The development of the polyurethane industry is highly dependent on the technological level of the production process. The traditional production mode has long been constrained by the pain points of "high energy consumption, high pollution, high dependence, and low efficiency" - fossil raw materials account for over 90%, intermittent process energy consumption accounts for 65% of the total production energy consumption, and the cost of VOCs emissions and hazardous waste treatment remains high. Restrict the sustainable development of the industry. In recent years, with the penetration of green manufacturing and intelligent manufacturing technologies, a series of disruptive technologies have emerged in the polyurethane production process, revolutionizing the entire chain from raw materials, processes to waste treatment, and reshaping the industrial production system.

I. Green raw material Substitution Technology: Breaking the reliance on fossils and reconstructing the production input end

Traditional polyurethane production takes petroleum-based polyols and isocyanates produced by the phosgene method as core raw materials. This not only greatly affects international oil price fluctuations but also poses a risk of highly toxic intermediates in the production of isocyanates by the phosgene method. New production technologies achieve dual breakthroughs in "carbon reduction and risk reduction" through innovations in the raw material end:

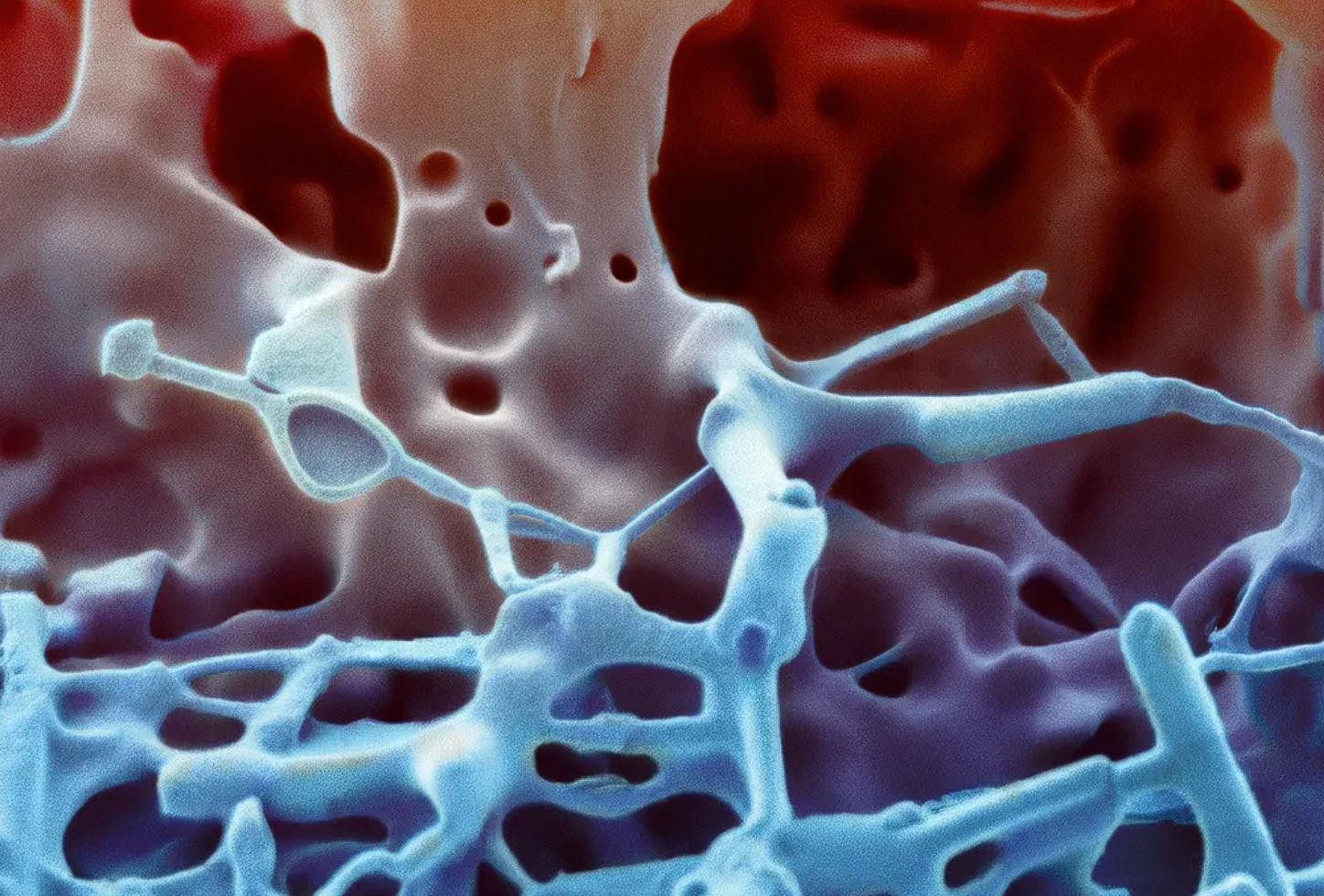

Large-scale preparation technology of bio-based polyols: Using renewable resources such as castor oil, soybean oil, and straw cellulose as raw materials, highly active bio-based polyols are prepared through enzyme-catalyzed transesterification and directional hydroxylation processes. At present, the third-generation bio-based polyol technology has achieved precise control of hydroxyl values (200-600mgKOH/g), with the proportion of replacing fossil-based polyols reaching over 80%. The carbon emissions during the production process are reduced by 45% compared to traditional processes, and the hydrolysis resistance of the products is improved by 30%. It has been applied in the production of furniture sponge and automotive seats. The raw material cost is 12% to 18% lower than that of petroleum-based products.

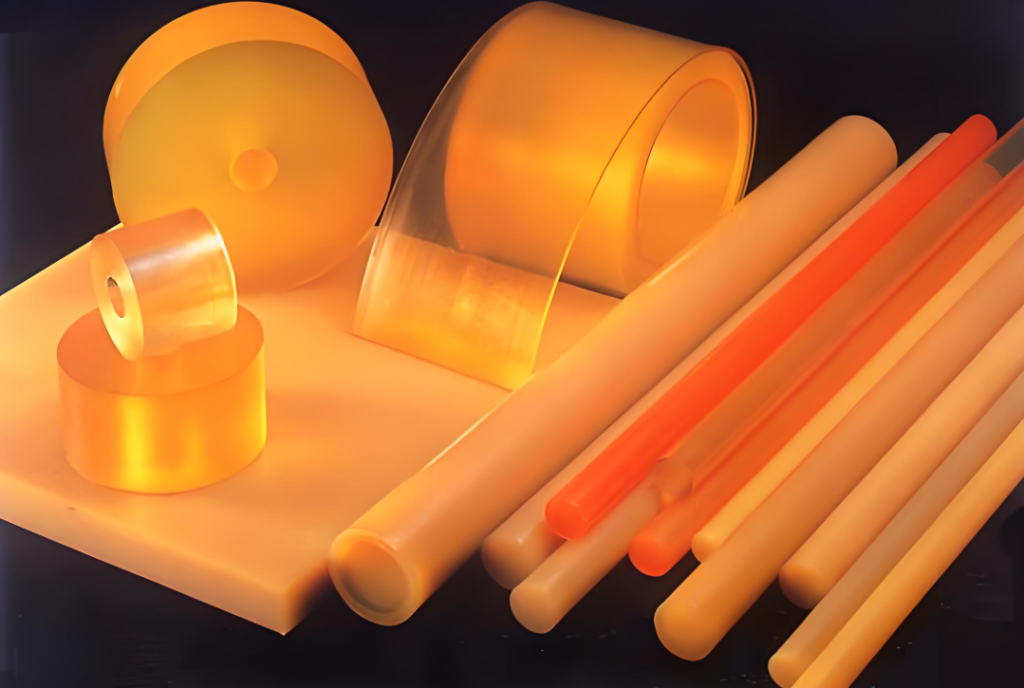

Non-phosgene isocyanate production technology: Breaking through the technical barriers of the traditional phosgene method, the carbamate thermal decomposition method is adopted, using carbon dioxide and amine compounds as raw materials, and under the action of a new type of metal-organic framework catalyst (MOFs), isocyanates are synthesized in one step. This technology eliminates the highly toxic risk of phosgene, with a reaction conversion rate of 99.2% and only water as a by-product. Currently, a 10,000-ton production line has been built, and the product purity reaches 99.9%, which can be directly used in the production of high-end polyurethane elastomers.

Ii. Continuous intelligent Production Process: Enhance efficiency and accuracy, and optimize the production process end

The traditional batch production process has problems such as long reaction time (8-12 hours per batch), large parameter fluctuations (product qualification rate is only 85%-90%), and frequent manual intervention. Continuous intelligent production technology achieves an upgrade of the entire production process through process reconstruction and digital empowerment.

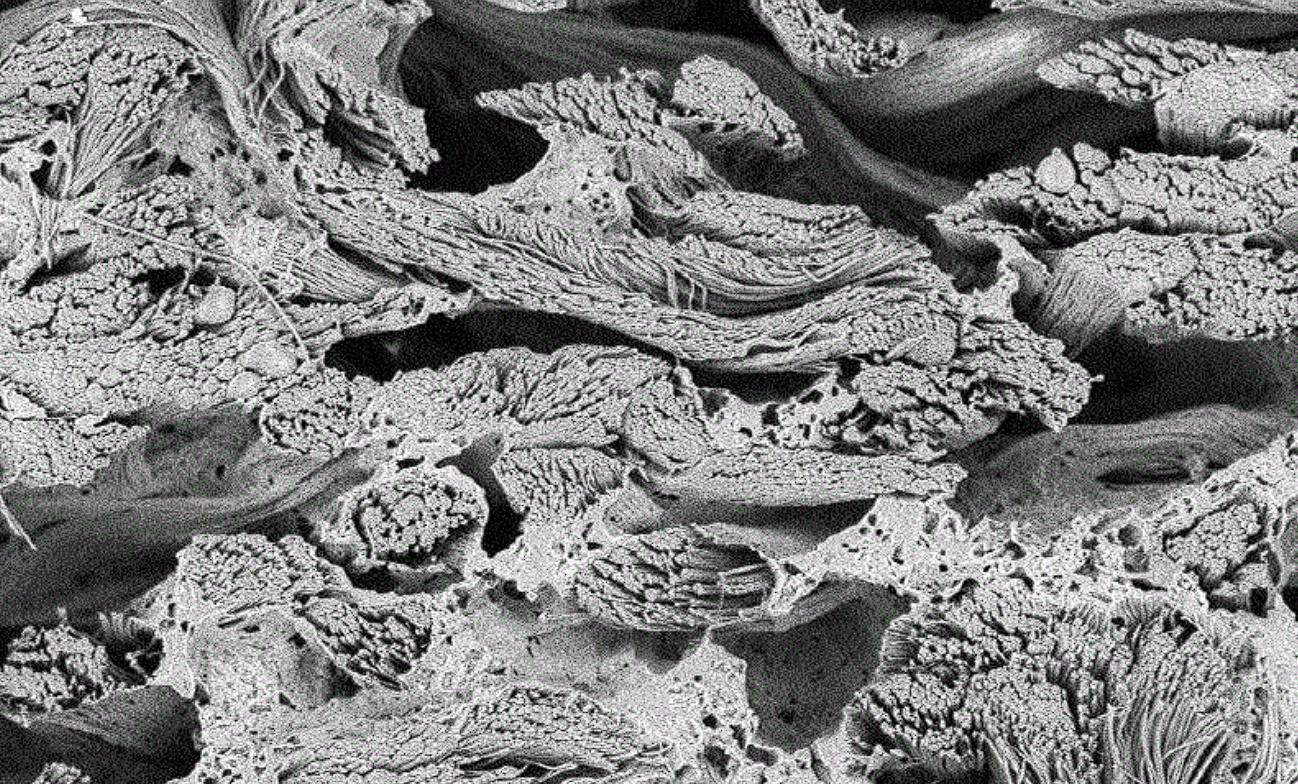

Continuous polymerization reaction system: It adopts a combined device of tubular reactor and static mixer to achieve real-time mixing and continuous reaction of raw materials such as polyols, isocyanates and catalysts. The reaction process was monitored in real time through online infrared spectroscopy (FTIR), and the temperature (control accuracy ±1℃) and flow rate (control accuracy ±0.5%) were automatically adjusted by AI algorithms. The reaction time was shortened to 1-2 hours, the production efficiency was increased by 600%, and the molecular weight distribution width of the product was reduced from 2.5 to 1.8. The performance stability has been significantly improved.

Modular flexible production technology In response to the demand for multi-variety and small-batch polyurethane products, a modular production unit that can be quickly switched has been developed. By replacing the reaction chamber and adjusting the formula parameters, the rapid production conversion of different types of products such as sponge, elastomer, and coating can be achieved. The switching time has been shortened from the traditional 48 hours to 2 hours, and the equipment utilization rate has been increased to over 90%. Meet the demands of customized production.

Iii. Clean Production and Recycling Technologies: Reducing environmental load and improving the production end

The treatment of by-products and energy consumption control during the production process are the key links in the green production of polyurethane. New technologies achieve closed-loop optimization at the production end through "reduction, reuse and resource utilization".

Reaction by-product recovery technology: For the hydrogen chloride by-product generated in the production of polyurethane prepolymers, a low-temperature adsorption-desorption system has been developed to increase the hydrogen chloride recovery rate to 99.5%, which can be directly used to prepare industrial-grade hydrochloric acid, reducing hazardous waste emissions by over 5,000 tons per 10,000 tons of production capacity annually. Meanwhile, through the reaction heat recovery device, the heat released by the polymerization reaction is used for preheating raw materials, reducing production energy consumption by 25% to 30%.

Zero discharge technology for production wastewater By adopting the combined process of "advanced oxidation + membrane separation + evaporation crystallization", the cleaning wastewater and condensate water in polyurethane production are treated. The COD removal rate reaches 99.8%, the salt retention rate exceeds 99%, and the water reuse rate after treatment is over 80%, achieving "zero discharge" of production wastewater. It can save 12,000 tons of fresh water per 10,000 tons of production capacity annually.

Iv. Technology Implementation Case: Practice from Laboratory to Industrialization

At present, leading domestic polyurethane enterprises have taken the lead in laying out new production technologies: A certain enterprise has adopted the "bio-based polyol + continuous polymerization" technology to build a 50,000-ton environmentally friendly polyurethane sponge production line annually. The VOCs emissions are reduced by 92% compared with traditional production lines. The products have passed the EU ECOCERT certification and are supplied to car manufacturers such as BMW and Volkswagen. A certain chemical enterprise has implemented a non-phosgene isocyanate project with an annual output of 30,000 tons of products. The energy consumption per ton of product is reduced by 380 kilograms of standard coal compared to the phosgene method, and it has been awarded the title of a national green factory demonstration project.

Future outlook: The direction of "deep iteration" in production technology

In the future, polyurethane production technology will advance towards "extreme greenness, comprehensive intelligence, and resource recycling" : At the raw material end, the production technology of CO₂ -based polyurethane is expected to break through (preparing polyols by copolymerizing CO₂ and propylene oxide), achieving "carbon fixation" production. At the process end, digital twin technology will be applied throughout the entire production process. By optimizing reaction parameters through virtual simulation and predicting equipment failures, production efficiency will be further enhanced. At the recycling end, the depolymerization and recycling technology of waste polyurethane will be deeply integrated with the production process, achieving a closed loop of "product - waste - raw material", and promoting the polyurethane industry to enter the era of "waste-free production".