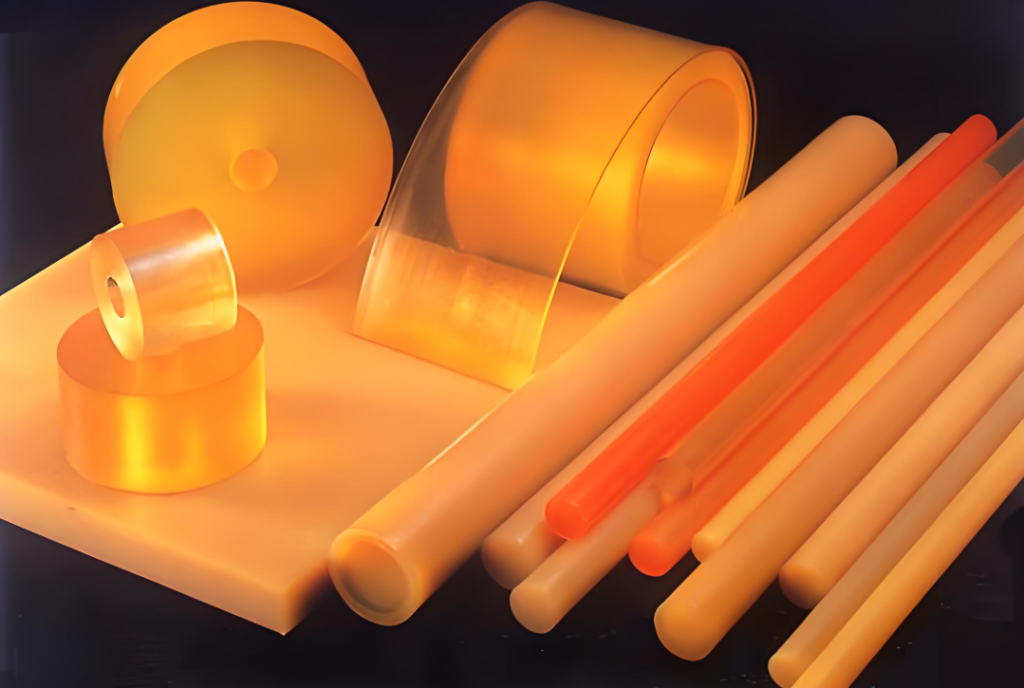

Polyurethane artificial leather (PU leather) is widely used in fields such as shoe materials, furniture, automotive interiors, and luggage due to its advantages of high simulation, strong weather resistance, and controllable cost. However, during the production process, pinhole defects (tiny holes with diameters ranging from 0.1 to 1mm, mostly circular or irregular in shape) are high-frequency quality issues. They not only directly disrupt the consistency of appearance but also reduce the core performance of the product such as water resistance and flex resistance, leading to an increase in rework rates and customer complaints. The following is a thorough analysis from three aspects: causes, impacts, and solutions.

The core cause of pinhole defects: It is due to the superposition of multiple factors

The production of PU leather involves the entire process of "base fabric pretreatment - coating (dry method/wet method) - foaming - curing - surface treatment". The occurrence of pinhole defects is closely related to the characteristics of raw materials, process parameters, equipment status and environmental control. Specifically, it can be divided into four major categories:

(1) Raw material stage: "Inherent Risks" of Resins and Additives

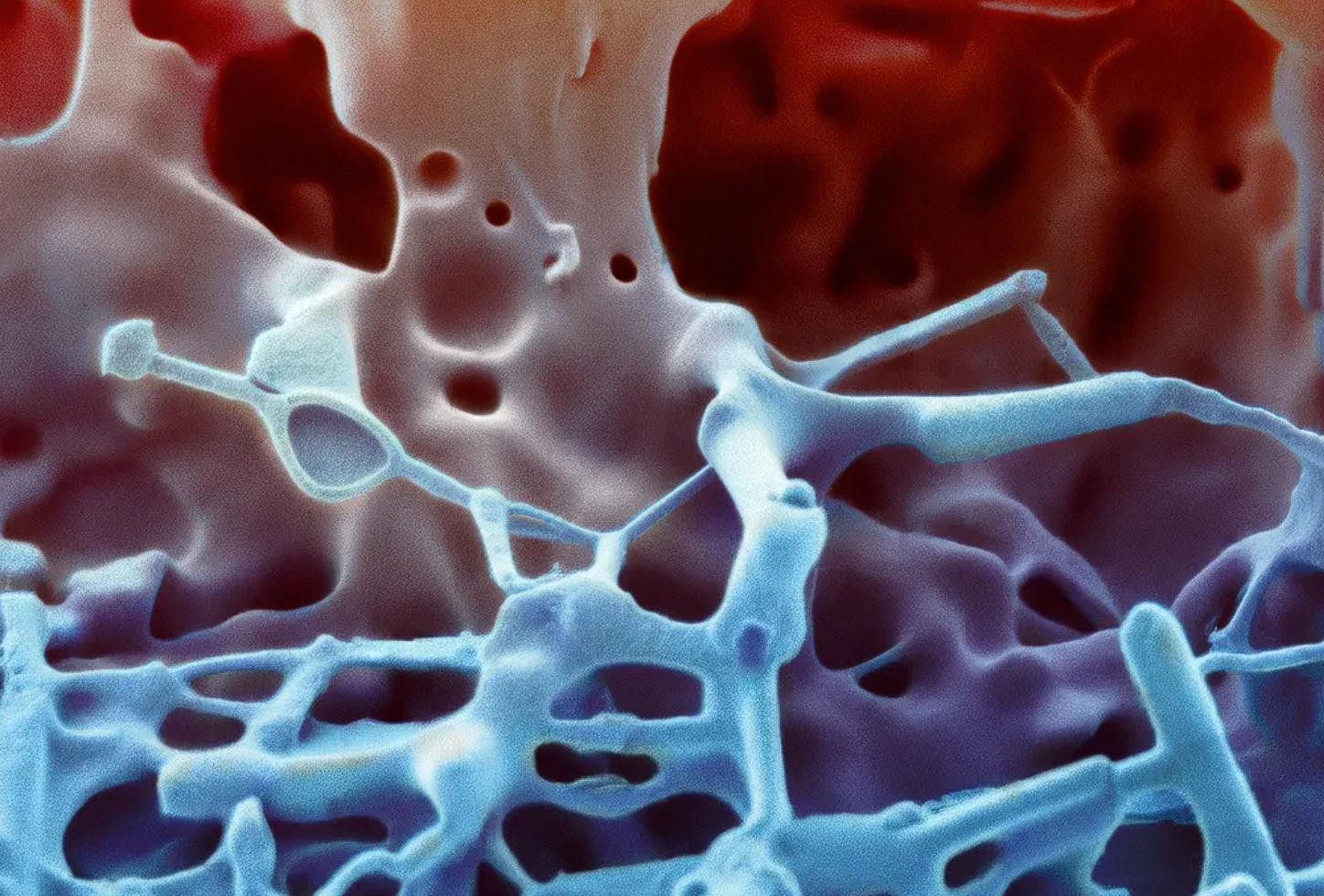

Polyurethane resin contains bubbles/impurities

When air is drawn in during resin synthesis or stirring, if vacuum degassing is not thorough (such as vacuum degree < -0.09MPa, degassing time < 30 minutes), the remaining tiny bubbles will expand when heated after coating and burst, forming pinholes.

During the storage of resin, dust and mechanical impurities (such as metal shavings and fiber filaments) are mixed in. When applied, voids form around the impurity particles. After curing, the impurities fall off, leaving pinholes. A certain PU leather factory for shoe materials once saw the pinhole rate caused by impurities rise from 0.5% to 8% due to the damage of resin filter bags (200 mesh).

The solvent evaporation rate is unbalanced

When dry PU leather is coated, the resin system needs to form a film through the evaporation of solvents (such as DMF, toluene). If the solvent ratio is inappropriate (for example, the proportion of fast-evaporating solvent is too high > 40%) or the ambient temperature rises suddenly, the surface solvent evaporates rapidly to form a dense film. The internal solvent, after being heated and vaporized, cannot escape and can only break through the surface film layer to form pinholes (commonly known as "bursting holes"). For instance, a certain furniture leather enterprise did not adjust the solvent ratio in summer. Due to the workshop temperature reaching 35℃, the pinhole defect rate increased sharply by 12%.

The compatibility of additives is poor

Insufficient addition of defoamers (such as silicone-based ones) (< 0.3%) or uneven dispersion cannot effectively suppress the bubbles generated during resin stirring. Excessive leveling agent (> 0.8%) may cause differences in the local solvent evaporation rate, resulting in tiny depressions that visually resemble pinholes.

(2) Production Process: "Acquired Deviation" in Parameter Control

The coating process parameters are inaccurate

When dry coating is applied, if the gap between the scraper is too small (< 0.1mm) or the coating speed is too fast (> 15m/min), the resin cannot be evenly spread on the surface of the base fabric, which is prone to form local "thin spots". After the solvent evaporates, pinholes are likely to occur in these areas.

When wet curing occurs, if the concentration of the curing bath (DMF aqueous solution) is too high (> 25%) or the temperature is too low (< 20℃), the curing speed of the resin coating is too fast. The internal DMF cannot fully diffuse into the bath solution, and the remaining DMF vaporizes to form pinholes. A certain automotive interior leather factory once had to rework a batch of products due to an out-of-control concentration of the solidification bath, resulting in a pinhole rate exceeding 15%.

Fluctuations in foaming and curing temperatures

When the temperature during the foaming stage is too high (> 120℃), the decomposition rate of the foaming agent (such as AC foaming agent) is too fast, and the amount of gas produced exceeds the load-bearing capacity of the resin film layer. After the bubbles burst, pinholes are formed. Abnormal temperature curves of the curing furnace (such as temperature > 160℃ at the front end and < 80℃ at the back end), incomplete resin cross-linking, insufficient surface film strength, and prone to pinholes due to minor stress.

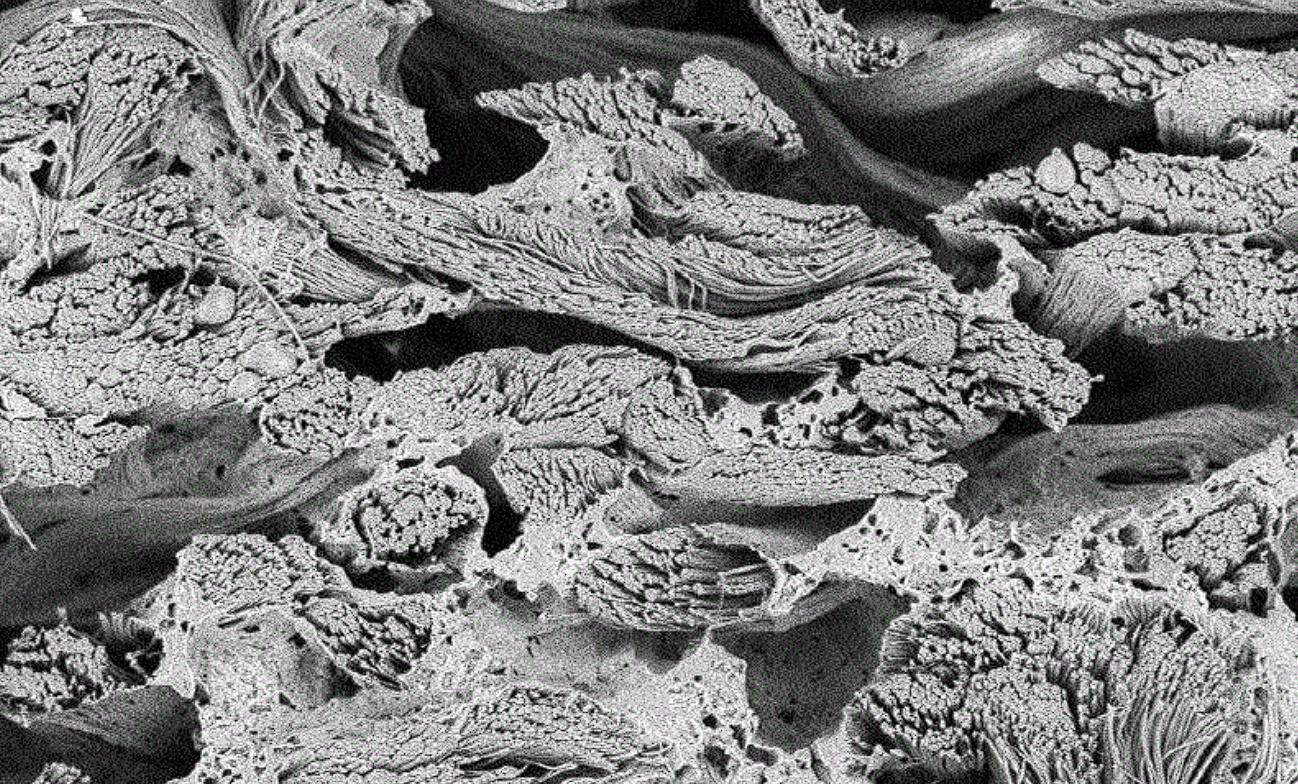

The pretreatment of the base fabric is not thorough

If the surface of the base fabric (such as knitted fabric or non-woven fabric) has oil stains, lint or dust, the resin cannot bond closely with the base fabric during coating. Pinholes will form at the areas where oil stains evaporate or lint falls off. If the moisture content of the base fabric is too high (> 8%), the moisture will vaporize when heated after coating, which may also puncture the resin film layer and cause pinholes.

(3) Equipment and Environment: "Hidden Interference" between Hardware and Environment

Insufficient equipment accuracy or improper maintenance

Scratches, dents (depth > 0.05mm) on the surface of the coating roller, or parallelism deviation of the roller shaft (> 0.1mm/m) will cause uneven thickness of the resin coating, and pinholes are prone to occur in thin areas.

The air ducts inside the curing oven are blocked, the hot air distribution is uneven, and the temperature in some local areas is too high, causing abnormal solvent evaporation and forming pinholes.

The cleanliness of the production environment is low

The concentration of dust particles in the workshop air exceeded the standard (> 100,000 grade), and the dust adhered to the surface of the uncured resin coating. After curing, the dust fell off, leaving pinholes. Uncontrolled humidity (< 40% or > 70%), low humidity accelerating solvent evaporation, and high humidity causing moisture absorption on the resin surface may all induce pinholes.

Ii. Main Impacts of pinhole defects: Comprehensive loss from appearance to performance

The appearance and pass rate have declined

PU leather has strict requirements for appearance. Even if the pinholes are very small (such as 0.2mm), they are clearly visible on the surface of light-colored or high-gloss products, which directly leads to product degradation or scrapping. Statistics from a certain luggage leather enterprise show that pinhole defects account for 35% of the total appearance non-conformities, with an annual loss of over 2 million yuan.

Core performance degradation

Water resistance: Pinholes can damage the dense film layer of PU leather, allowing rainwater and sweat to seep in. If pinholes appear in the PU leather used for shoes, it will cause a "water seepage" problem, affecting the wearing experience.

Bending resistance: The pinhole area is a stress concentration point. During repeated bending (such as in shoe uppers and sofa armrests), it is prone to cracking, and the service life is shortened by more than 50%.

Stain resistance: Pinholes are prone to accumulate dust and oil stains, which are difficult to clean and affect the appearance and hygiene of the product (such as PU leather for children's products).

The industry application is limited

In high-end fields (such as automotive interior leather and medical PU leather), there is zero tolerance for pinhole defects: If automotive interior leather has pinholes, it will affect the sealing performance and aesthetics inside the vehicle and cannot pass the inspection of the original equipment manufacturer. The pinholes in medical PU leather (such as surgical gowns and protective equipment) can damage the protective barrier and pose a risk of bacterial penetration.

Iii. Solution and Prevention of Pinhole Defects: Full-Process Control Plan

In view of the multi-cause characteristics of pinhole defects, it is necessary to formulate control measures throughout the entire chain from "raw materials - process - equipment - environment" to achieve source prevention and process control:

(1) Raw Material Control: Strengthening the quality foundation

Resin and solvent optimization

High-purity PU resin (impurity content < 0.1%) is selected. During stirring, the rotational speed is controlled (< 600r/min). Two-stage vacuum degassing (vacuum degree -0.095 MPa, time 40-60min) is adopted to ensure no residual bubbles.

Adjust the solvent ratio according to the ambient temperature: in summer (> 30℃), increase the proportion of slow-volatile solvents (such as DMF to 50%), and in winter (< 15℃), increase the proportion of fast-volatile solvents (such as toluene to 35%) to avoid an imbalance in the evaporation rate.

Precise addition of additives

The addition amount of defoamer (such as BYK-052) should be controlled at 0.3%-0.5%, and uniform dispersion should be ensured through a high-speed disperser (1200r/min). The addition amount of leveling agents (such as TEGO-450) should be no more than 0.6% to avoid excessive use causing abnormalities.

(2) Process Optimization: Precise control of parameters

Standardization of coating process

Dry coating: Adjust the scraper gap (0.15-0.3mm) according to the product thickness, and control the coating speed at 8-12m/min to ensure uniform coating.

Wet coagulation: The concentration of the coagulation bath is stabilized at 18%-22%, the temperature is controlled at 25-30℃, and the DMF content is monitored in real time, with pure water replenished promptly.

Calibration of foaming and curing curves

The foaming temperature is controlled at 100-110℃. The curing furnace adopts a "gradient temperature rise" curve (120-140℃ in the front section, 150-160℃ in the middle section, and 80-100℃ in the back section) to ensure that the resin is fully cross-linked and the solvent is completely evaporated.

Pre-treatment strengthening of base fabric

The base fabric is dried at high temperature (120℃) to a moisture content of less than 5%. The surface oil stains and lint are removed by a plasma cleaner, and then coated with resin filtered through a 200-mesh filter screen to reduce the interference of impurities.

(3) Equipment and Environmental Assurance: Eliminating Hidden risks

Regular maintenance of equipment

The surface flatness of the coating roller should be inspected every shift. Any scratches found should be polished in time (roughness Ra < 0.8μm). The parallelism of the roller shafts is calibrated monthly, with the deviation controlled within < 0.05mm/m.

The air duct of the curing oven should be cleaned every quarter to ensure the uniformity of the hot air (temperature difference < ±5℃). A 150-mesh filter is installed on the resin conveying pipeline to prevent impurities from entering the coating system.

Environmental cleanliness control

The workshop adopts the 10,000-level clean workshop standard, equipped with air purifiers and humidity control systems (humidity 50%-60%), and windproof curtains are set up in the coating area to prevent sudden temperature changes. Operators should wear dust-free suits and gloves to reduce human contamination.

(4) Detection and Traceability: Timely identify problems

Online detection

Install a high-definition visual inspection system (resolution > 2000dpi) at the outlet of the curing oven to identify pinhole defects in real time (detection accuracy 0.05mm). Stop the machine immediately for adjustment upon detecting any abnormality.

Offline spot inspection

For each batch of products, in accordance with the standard of GB/T 38443-2020 "Polyurethane Artificial Leather and Synthetic Leather", 5 square meters of samples are randomly selected and visually inspected under a 40W fluorescent lamp (50cm away). The number of pinholes should be ≤2 per square meter (≤1 per square meter for high-end products).

Iv. Industry Case: Practical Experience in Solving Pinhole Defects

A certain PU leather enterprise for shoes once faced order loss due to a pinhole defect rate exceeding 10%. After rectification through the following measures, the defect rate dropped to 0.8%

Raw material end: The resin deaeration time was extended from 20 minutes to 45 minutes, and the proportion of fast-volatile solvents in the solvent ratio was reduced from 45% to 30%.

At the process end: The coating speed was reduced from 18m/min to 12m/min, and the curing bath temperature was raised from 18℃ to 28℃.

Equipment end: Replace the coating roller (surface Ra=0.4μm), clean the air duct of the curing furnace, and install a 150-mesh filter;

Environmental end: The humidity in the workshop is controlled at 55%, and the cleanliness level is raised to 10,000 grade.

Summary and Prospect

The pinhole defect of polyurethane artificial leather is a quality issue caused by the superposition of multiple factors and needs to be prevented through meticulous control throughout the entire process. In the future, with the application of technologies such as solvent-free PU resin (to avoid solvent evaporation issues), intelligent coating equipment (real-time parameter adjustment), and nano-scale defoamers (highly efficient anti-foaming), the pinhole defect rate will be further reduced. Meanwhile, the industry needs to improve the classification standards for pinhole defects (such as dividing them by diameter into micro-pinholes < 0.1mm, small pinholes 0.1-0.5mm, and large pinholes > 0.5mm), to provide precise quality control basis for different application scenarios.