Polyurethane elastomers, with their outstanding mechanical properties, wear resistance and chemical corrosion resistance, occupy an important position in high-end fields such as mechanical seals, automotive manufacturing and medical equipment. The precise control of its performance and stable production are highly dependent on the scientific combination of various additives - although the addition amount of additives only accounts for 0.1% to 30% of the total formula, it can achieve a leapfrog improvement in product quality from dimensions such as synthesis efficiency, processing performance, and service life. The following is an analysis of the core additive system and its application logic from a functional perspective.

I. Synthetic Core Additives: The key to Constructing the molecular skeleton of elastomers

Such additives directly participate in the growth of polyurethane chains and crosslinking reactions, determining the basic structure and mechanical basis of elastomers, and serve as the "regulatory center" of the synthesis process.

1. Catalyst: Precisely control the reaction rate

The catalyst precisely controls the polymerization rate by reducing the activation energy of the reaction between isocyanate (NCO) and polyol (OH). According to the catalytic mechanism, it can be divided into two categories:

Tertiary amine catalysts: represented by triethylenediamine and dimethylethanolamine, they mainly catalyze the foaming reaction between NCO and water. When used in combination with tin-based catalysts in polyether-based elastomers, they can optimize the molecular chain distribution. In the production of a certain CPU (cast polyurethane elastomer), adding 0.3% triethylenediamine can shorten the gel time from 40 minutes to 12 minutes, and the tensile strength of the product remains above 35MPa.

Organometallic catalysts: Organotin compounds such as dibutyltin dillaurate and stannous octoate are the mainstream, which can specifically catalyze the chain growth reaction of NCO and OH, making the reactivity of high-molecular-weight and low-molecular-weight polyols converge, and the molecular weight distribution width of the prepolymer decreases from 2.5 to below 1.8. Suzhou Xiangyuan New Materials has adopted customized organotin catalysts in the preparation of elastomers, which has increased the reaction conversion rate to 99.5% and enhanced the batch stability of products by 40%.

2. Chain extenders and crosslinking agents: Define the boundaries of mechanical properties

This type of additive determines the hardness, elasticity and heat resistance of elastomers by extending molecular chains or constructing three-dimensional networks, and is the "core module" for performance customization:

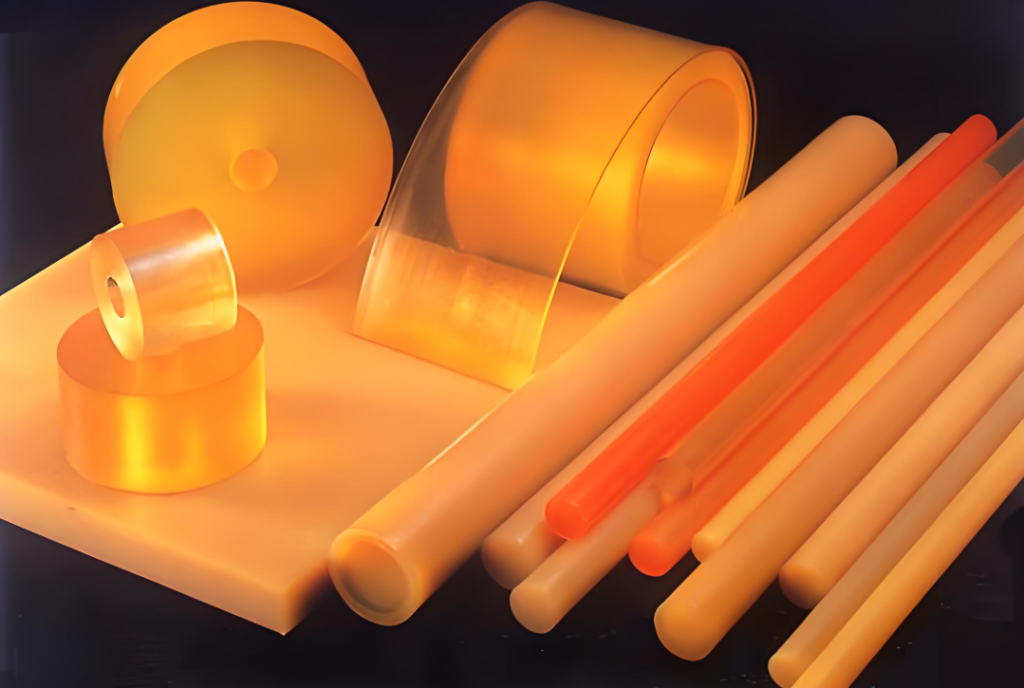

Diol chain extenders: 1, 4-butanediol (BDO) is the preferred choice for thermoplastic polyurethane elastomers (TPU), and the Shore hardness can be adjusted from 70A to 85D by regulating the dosage. Hydroquinone dihydroxyethyl ether (HQEE) can significantly enhance the heat resistance of elastomers, increasing the heat distortion temperature by more than 30℃, and is suitable for high-temperature scenarios such as oil well seals. The XYlink HQEE from Suzhou Xiangyuan has excellent compatibility with MDI prepolymers, and the wear resistance of the forklift tires made from it is improved by 50%.

Diamine chain extenders: 3,3' -dichloro-4,4' -diphenylmethanediamine (MOCA) is a classic variety. The chlorine substituents on the benzene ring can extend the service life in the reactor to over 30 minutes, facilitating manual pouring operations. It is widely used in the production of bridge shock absorption components. Its upgraded product, XYlink 311, is a heat-sensitive delayed reaction curing agent that can achieve uniform crosslinking even in a low-temperature environment of -10 ℃.

Crosslinking agents: Polyol crosslinking agents such as trimethylolpropane and pentaerythritol form carbamate crosslinking points in the mixed elastomer, reducing the compression set from 25% to below 8%. Allyl ether diols can introduce unsaturated bonds into the molecular chain, providing active sites for subsequent vulcanization.

Ii. Processing modification AIDS: Optimize production efficiency and molding quality

This type of additive focuses on solving the processing problems of elastomers, reducing the energy consumption of molding, and enhancing the appearance and practicality of products. It serves as an "efficiency booster" in the production process.

1. Demolding and lubricating additives: Ensure smooth molding

Polyurethane has strong polarity and is easy to bond with molds. Mold release agents are indispensable processing AIDS.

Traditional mold release agents: Silicone oil and silicone ester products are widely used in CPU production. A certain automotive sealing parts enterprise adopted a 5% silicone oil mold release agent, which increased the mold turnover rate to three times per hour. Paraffin-based mold release agents are suitable for low-hardness TPU products, and the surface gloss after demolding can reach over 90%.

Environmentally friendly upgraded type: Water-based mold release agent PRW-105 is non-toxic and has no VOC emissions. One application can continuously produce 15 products. It has completely replaced solvent-based products in the production of medical catheters, and the waste rate has been reduced from 8% to 1.5%.

Lubricants: Adding 0.5% to 1% of zinc stearate and stearamide during TPU extrusion can increase the melt flow rate by 20% and prevent sharkskin defects on the pipe surface.

2. Fillers and plasticizers: Balancing cost and performance

Physical modification to achieve performance enhancement and cost optimization is a "cost-performance solution" for mid-to-low-end products:

Filler: Adding 20% of the easily mixed channel black to the mixed elastomer can reduce the cost by 12% while maintaining the tensile strength of ≥20MPa. Adding 15% glass fiber to RIM (Reaction Injection Molding) products increases the flexural modulus to 3000MPa and reduces the coefficient of thermal expansion by 40%. Medical-grade elastomers are made of nano-grade silica. Adding 5% of it can keep the transparency above 90%.

Plasticizers: Polar plasticizers such as trimethylene phosphate and coumarone resin, when added to the compound rubber at 10%, can reduce the Shore hardness by 15 degrees and improve the low-temperature toughness (no brittleness at -40℃), but the dosage should be controlled below 15% to prevent blooming and a decrease in wear resistance.

3. Functional modification additives: Expand high-end application scenarios

New functional additives drive elastomers to break through into high value-added fields:

Transparency enhancer: 嶅 the Clear-700 silicone dispersant from ke can increase the light transmittance of TPU from 85% to 95% and reduce the haze to 1%. A certain medical enterprise successfully replaced imported materials with the catheters it produced, reducing the cost by 40%.

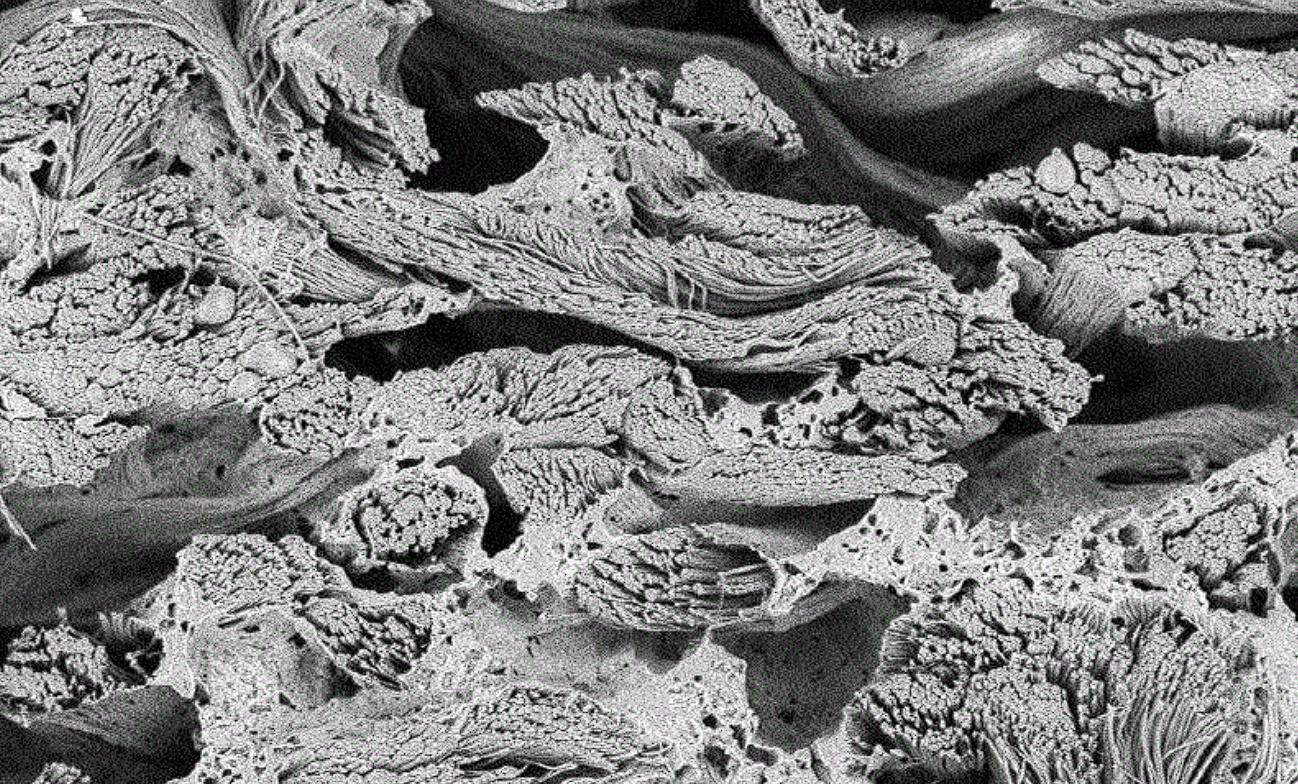

Anti-friction additive: The elastomer with 5% polytetrafluoroethylene (PTFE) micro-powder added has a friction coefficient reduced from 0.35 to 0.12, and the service life of the bearings made has been extended by three times. It has been applied to the sealing of high-end machine tool spindles.

Iii. Protective Stabilizing Additives: Extend the service life of products

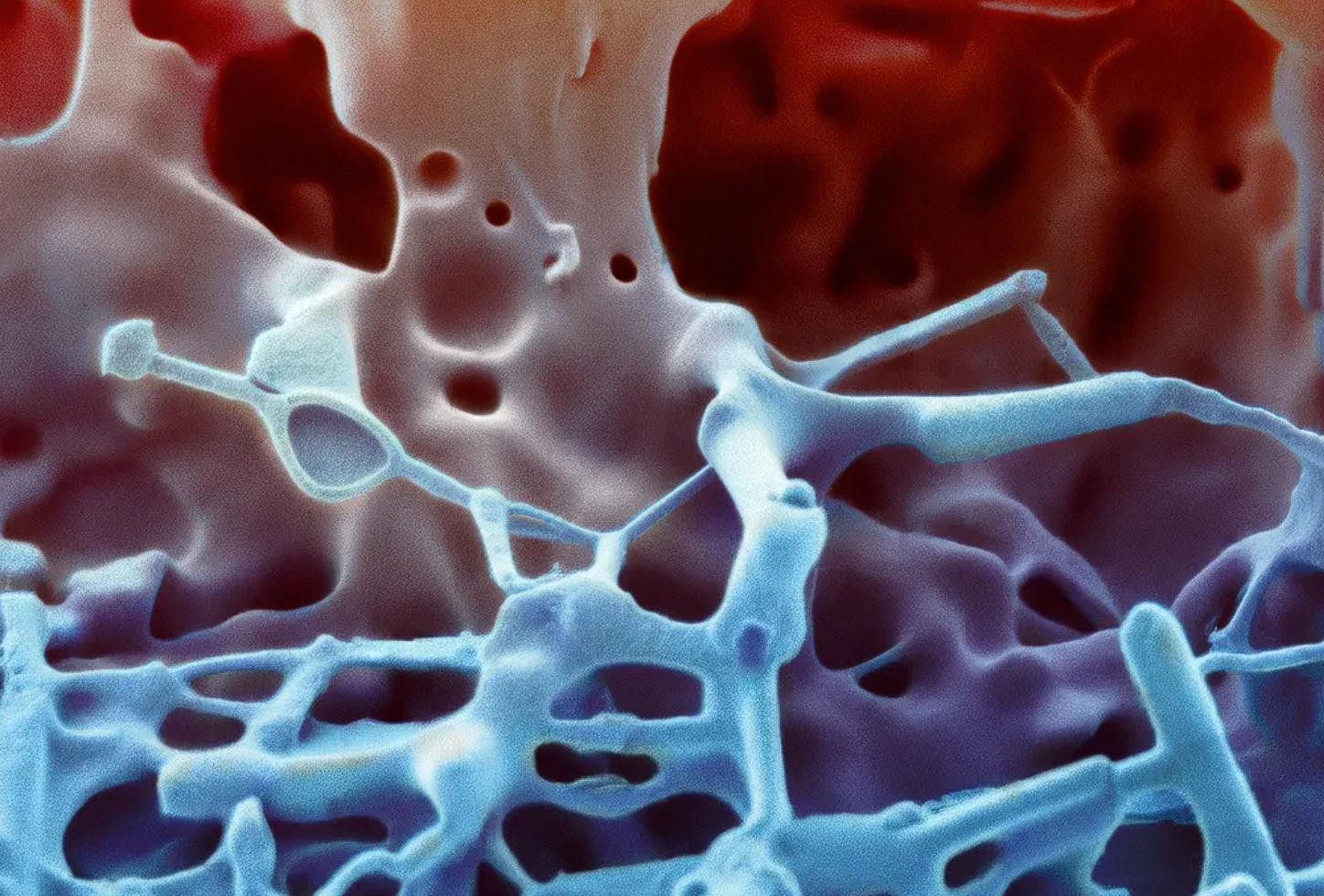

In response to the defect that polyurethane elastomers are prone to erosion by heat, oxygen and water, protective additives build a "three-dimensional protective network" to ensure long-term stability during use.

Antioxidant and light stabilizing additives

Antioxidant: The combination of tetra-[β-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester (antioxidant 1010) and trinonylphenyl phosphite can extend the thermal oxidative aging life of elastomers to more than 10 years. The liquid antioxidant Irganox 5057 has low volatility and a loss rate of only 2% during TPU melt processing.

Light stabilizers: Ultraviolet absorbers UV-327 and UV-328 can effectively inhibit the yellowing of MDI elastomers. Adding 0.5% can make the yellowing resistance grade reach above level 4, meeting the weather resistance requirements of automotive exterior parts.

2. Anti-hydrolysis additives

Carbodiimide derivatives react with carboxylic acids produced by hydrolysis to form stable acylureas, which increase the retention rate of elastomer elongation at break from 50% to 85% in a humid environment. After a certain underwater sealing parts enterprise adopted this type of additive, the service life of its products was extended from one year to three years.

Iv. Core Principles and Cases of Additive Application

1. Compatibility principle

Catalysts and chain extenders need to be regulated in a coordinated manner: In CPU production, the combined use of 0.2% dibutyltin dilaurate and MOCA can reduce the peak exothermic temperature of the reaction by 20℃, preventing the formation of bubbles inside the product.

The enhanced effect of protective additive compounding: When antioxidant 1010 and light stabilizer UV-327 are compounded in a 1:1 ratio, the protective effect is superior to that of using a single additive, and the total addition amount can be controlled below 0.8%.

2. Industrialization cases

Suzhou Xiangyuan New Materials customized a "HQEE + anti-hydrolysis agent + anti-wear agent" composite additive system for a certain car manufacturer. The polyurethane shock-absorbing block made from it has a compression set of ≤5%, and its oil resistance has been improved to ASTM D471 standard level 1, and it has passed the 100,000-kilometer driving test.

A certain medical TPU enterprise uses the combination of "Clear-700 anti-glare agent + antioxidant 1010" to produce infusion tubes with a light transmittance of 96%, and they can withstand wet heat aging (60℃/ 95%RH) for 1000 hours without cracking, meeting the EU CE certification standards.

Future development direction

With the upgrading of green manufacturing and high-end demands, additive technology is showing three major trends: First, environmental friendliness, solvent-based mold release agents are gradually being replaced by water-based products, and EU REACH-certified additives (such as low-toxicity MOCA derivatives) have become mainstream; Second, functional integration. Composite additives that have both toughening and anti-hydrolysis properties can reduce the complexity of the formula by 30%. The third type is the intelligent response type. Temperature-sensitive chain extenders have been applied in self-healing elastomers and can automatically repair micro-cracks to extend service life.