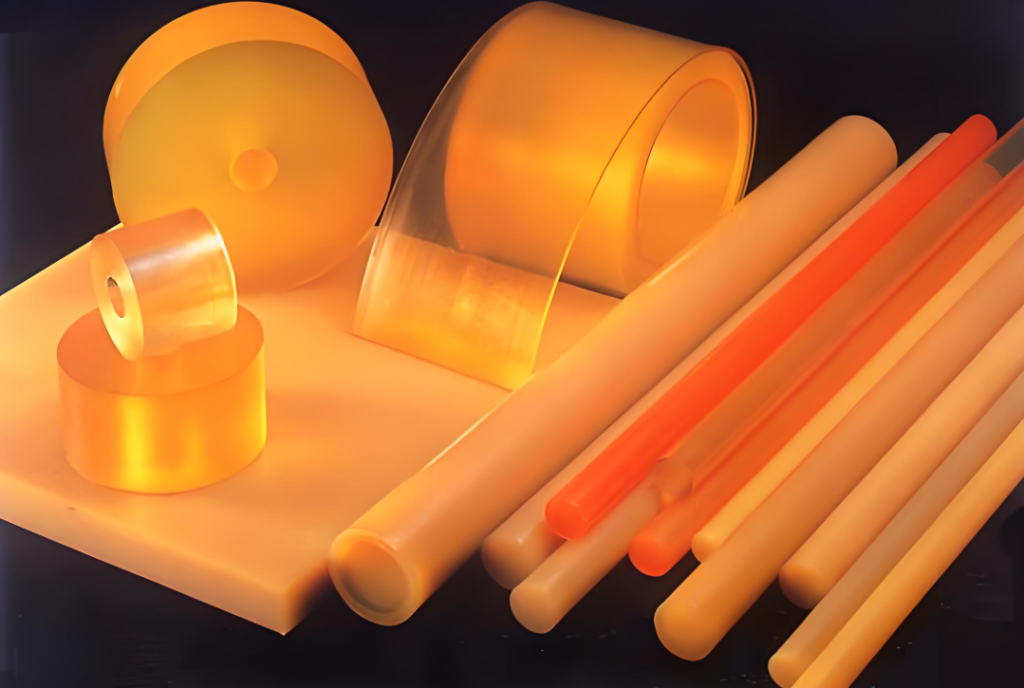

As a high-performance polymer material, urethane is widely used in numerous fields such as construction, automobiles, home appliances, and medical care. However, its traditional production mode has long been confronted with pain points such as environmental protection pressure, performance limitations, and resource dependence. In recent years, with the deep integration of materials science and the concept of green manufacturing, the polyurethane industry has witnessed a number of key technological breakthroughs. These not only have broken through the development bottlenecks of the industry but also expanded the application boundaries of materials, injecting strong impetus into the high-quality development of the industry.

Core technology breakthroughs: Three major directions lead industry transformation

Environmentally friendly synthetic technology: Say goodbye to pollution and achieve green production

In the traditional polyurethane synthesis process, the production of isocyanate raw materials and the use of solvents generate volatile organic compounds (VOCs) and hazardous waste, highlighting the prominent environmental protection pressure. The newly broken solvent-free polyurethane synthesis technology, by optimizing the reaction system and using highly efficient catalysts, can complete the polymerization reaction without adding organic solvents, reducing VOCs emissions by over 90%. Meanwhile, the realization of the upgrade of the continuous polymerization process has reduced energy consumption in the production process by 30% and increased the product yield to over 98%, solving the pollution problem of traditional processes from the source and meeting the industrial transformation needs under the "dual carbon" goals.

Bio-based polyurethane technology: Replacing fossil raw materials and practicing sustainable development

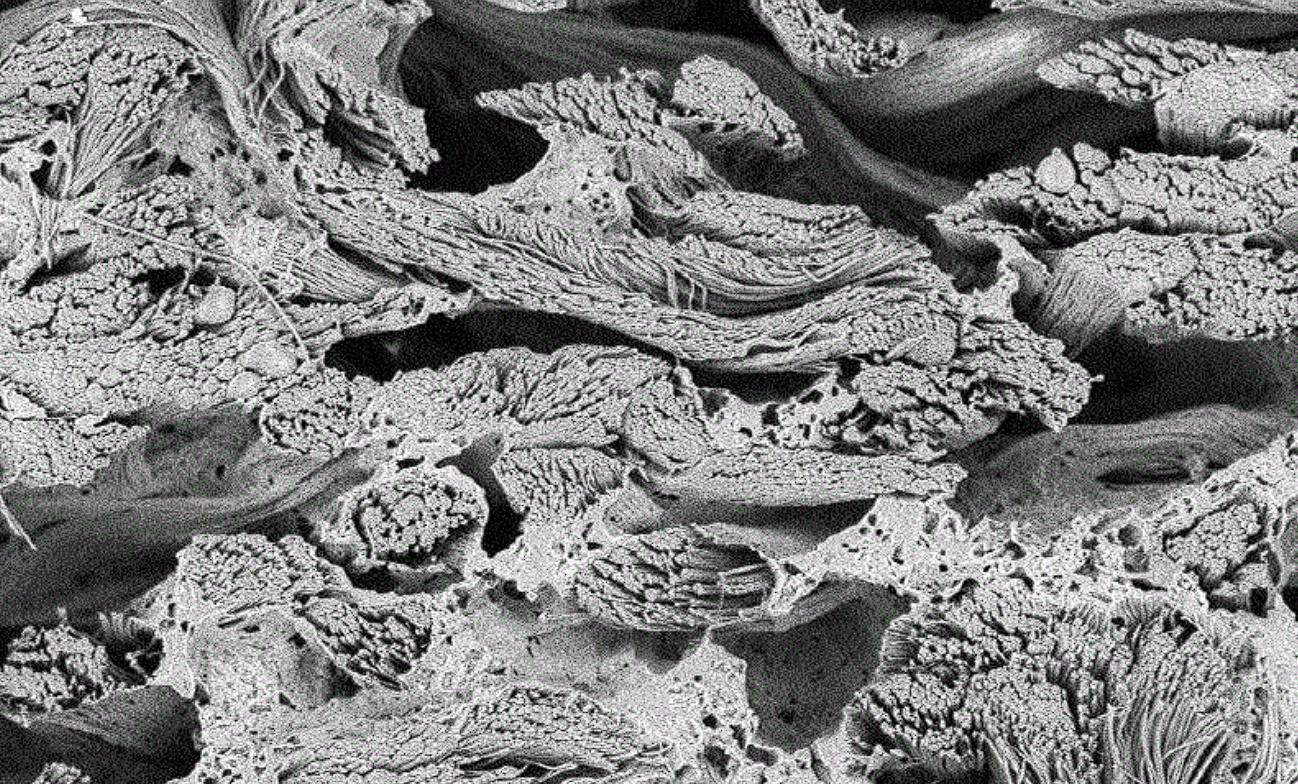

The bio-based polyurethane technology developed based on biomass resources has become the core direction of the industry's green transformation. This technology uses renewable resources such as vegetable oil, straw and waste biomass as raw materials, and prepares key intermediates such as polyols through processes like biological fermentation and chemical modification, replacing traditional fossil-based raw materials. Bio-based polyurethane not only retains the excellent properties of traditional materials such as wear resistance, heat insulation and elasticity, but also has degradability and can be decomposed into harmless substances by microorganisms in the natural environment. At present, polyurethane materials with high bio-based content (≥70%) have achieved large-scale production, with costs reduced by 15% to 20% compared to traditional fossil-based products. They are widely used in packaging, home textiles, automotive interiors and other fields.

High-performance modification technology: Precise upgrade to meet high-end demands

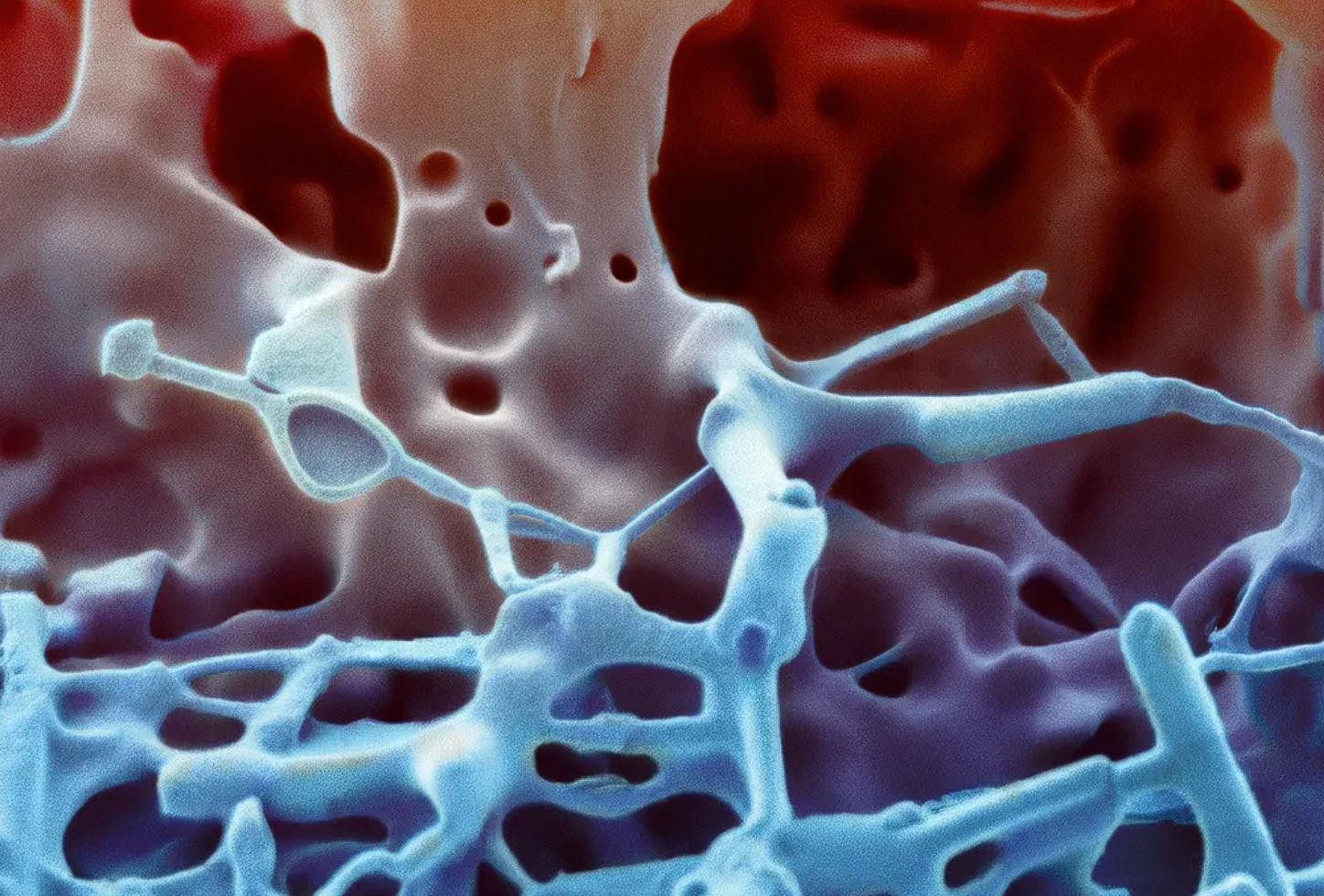

In response to the special requirements for polyurethane materials in the high-end manufacturing field, multiple breakthroughs have been achieved in high-performance modification technology. Through nanocomposite modification technology, nanomaterials such as graphene and carbon nanotubes are integrated into the polyurethane matrix, increasing the tensile strength of the material by more than 50% and the thermal conductivity by three times. This can meet the demands of high-end scenarios such as battery packaging for new energy vehicles and heat dissipation for electronic devices. In addition, the successful development of intelligent responsive polyurethane technology has endowed the material with environmental response capabilities such as temperature, humidity, and pressure. In the medical field, it can be used for intelligent wound dressings (automatically regulating humidity and releasing drugs), and in the construction field, it can be made into self-healing sealing materials, significantly enhancing the product's service life and application value.

Application scenario expansion: From basic materials to high-end intelligent manufacturing

The implementation of new technologies has continuously expanded the application scenarios of polyurethane materials. In the field of new energy, bio-based polyurethane composite materials, due to their lightweight and high strength characteristics, have become the preferred material for wind turbine blade core materials, helping wind power equipment reduce costs and increase efficiency. In the medical field, biocompatible modified polyurethane can be made into artificial heart valves, medical catheters and other devices, reducing the risk of rejection reactions in the human body. In the field of building energy conservation, the thermal conductivity of environmentally friendly polyurethane rigid foam insulation materials is as low as 0.018W/(m · K), and the insulation effect is 40% better than that of traditional materials, promoting the development of green buildings. In the high-end manufacturing field, modified polyurethane elastomers, with their excellent wear resistance and impact resistance, are widely used in key parts such as shock-absorbing components of high-speed railways and industrial mechanical seals.

Industry impact and Future outlook

The technological breakthroughs in the polyurethane industry not only promote the green transformation and quality upgrade of the industry itself, but also provide strong support for the development of downstream application fields. The popularization of environmental protection technologies has reduced the cost of environmental compliance in the industry. Bio-based technologies have alleviated the reliance on fossil resources, while high-performance technologies have helped China's high-end manufacturing industry break away from its reliance on imported materials and enhance its international competitiveness.

In the future, the technology in the polyurethane industry will evolve towards being "greener, more efficient and smarter". On the one hand, the conversion rate of bio-based raw materials will further increase, and it is expected to achieve large-scale application of 100% bio-based polyurethane. On the other hand, breakthroughs will continue in cutting-edge directions such as polyurethane materials for 3D printing and intelligent sensing polyurethane materials, to meet the demands of more emerging scenarios. With the continuous deepening of cooperation among industry, academia and research, and the sustained increase in policy support, the polyurethane industry will achieve leapfrog development through technological innovation, providing a Chinese solution for the sustainable development of the global materials industry.