Cold chain transportation, as the core circulation link for special goods such as fresh food, pharmaceutical products, and precision electronics, has extremely strict requirements for the "heat preservation, cushioning, and lightweight" of packaging. Polyurethane foam, with its excellent closed-cell structure insulation performance and customizable molding characteristics, has become the mainstream material for cold chain packaging. Its application not only directly affects the quality of goods transportation but also profoundly changes the cold chain logistics landscape from dimensions such as transportation radius, cost control, and greenness. The following is an analysis of its specific impact on transportation from four core dimensions.

1. Temperature stability: Extend the insulation effect and expand the transportation radius

The core pain point of cold chain transportation is "deterioration of goods caused by temperature fluctuations". The high insulation performance of polyurethane foam fundamentally solves this problem, creating greater time and space flexibility for transportation.

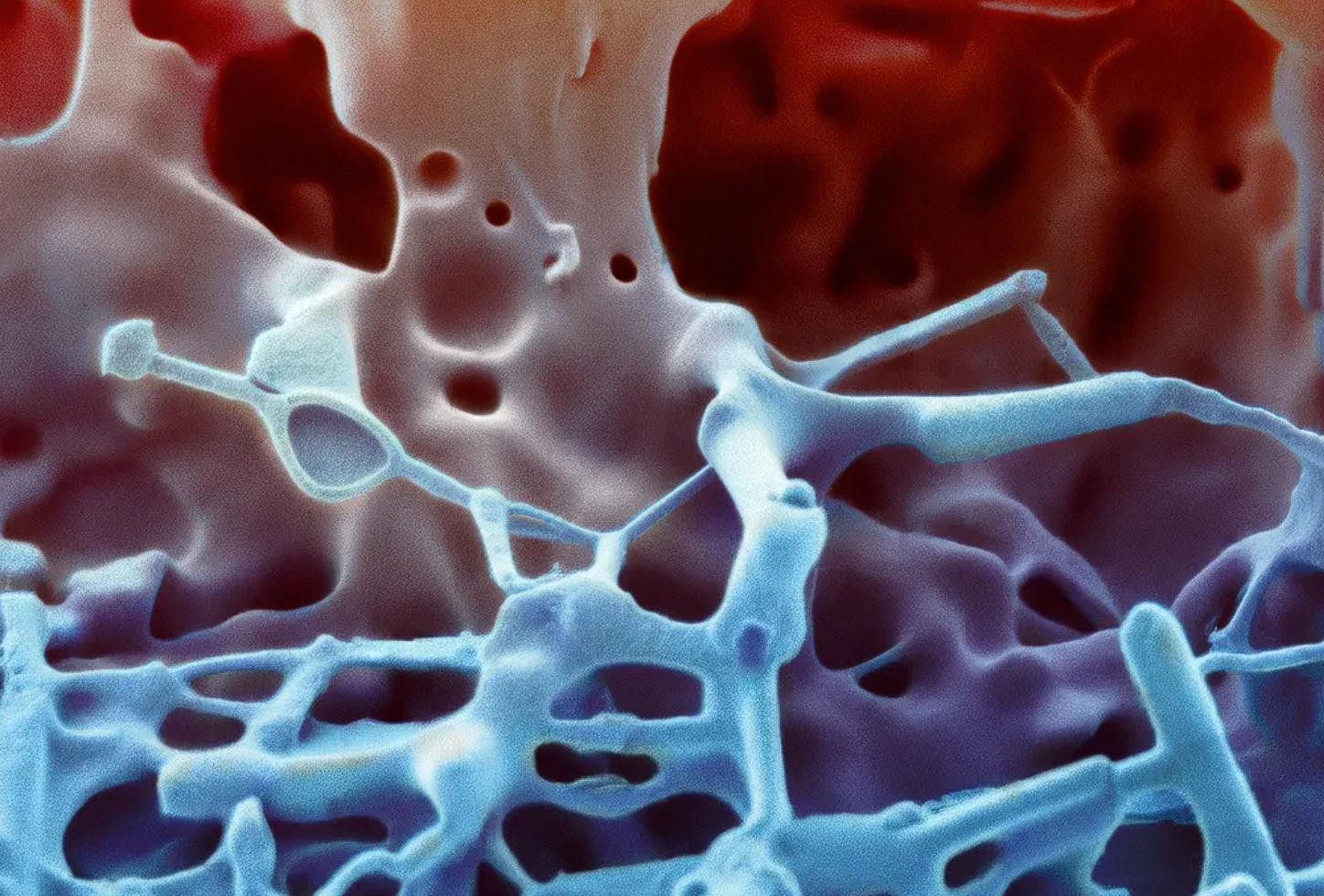

Long-term insulation support for long-distance transportation: The thermal conductivity of high-density polyurethane foam (density 30-50kg/m³) is as low as 0.022W/(m · K), which is far superior to that of EPS (polystyrene) at 0.033W/(m · K). Take the 20L polyurethane foam box commonly used in the pharmaceutical cold chain as an example. Under an initial temperature of -20 ℃ and an external environment of 30℃, it can maintain a temperature below -15 ℃ inside the box for up to 72 hours, which is 40% longer than the insulation time of EPS boxes. This enables temperature-sensitive goods such as vaccines and biological preparations to break through the traditional 48-hour transportation radius limit and achieve cross-regional or even cross-provincial transportation. For instance, after a certain biopharmaceutical company adopted this packaging, its transportation coverage expanded from 300 kilometers to 800 kilometers.

Temperature uniformity reduces the risk of local deterioration: The closed-cell rate of polyurethane foam is over 95%, which can effectively block air convection. The temperature difference between different areas inside the box is controlled within ±2℃, avoiding the deterioration of goods caused by local excessively high temperatures in traditional packaging. Data from a certain fresh food e-commerce platform shows that after using customized polyurethane foam pallets for packaging, the rot rate of strawberries during transportation has dropped from 12% to 3%, and the loss cost has decreased by 75%.

Second, Lightweighting and structural Compatibility: Enhance transportation efficiency and reduce logistics costs

In the cost of cold chain transportation, "load energy consumption" and "space utilization rate" account for more than 40%. The lightweight characteristics and customizable structure of polyurethane foam directly optimize transportation efficiency and cost structure.

Reduce weight and increase efficiency, enhancing the revenue per unit load: Under the same insulation effect, the weight of polyurethane foam packaging is 20%-30% lighter than that of traditional EPS packaging and over 60% lighter than that of metal insulation boxes. Take a 10-ton cold chain truck as an example. Using polyurethane foam packaging can reduce the self-weight of the packaging by about 500 kilograms, which is equivalent to loading an additional 500 kilograms of goods per trip. The annual additional transportation revenue is about 120,000 yuan (calculated based on an average profit of 2 yuan per kilogram for fresh produce and 200 trips per year). Meanwhile, lightweight packaging reduces the fuel consumption of trucks by 3% to 5% per 100 kilometers, saving over 8,000 yuan in fuel costs annually.

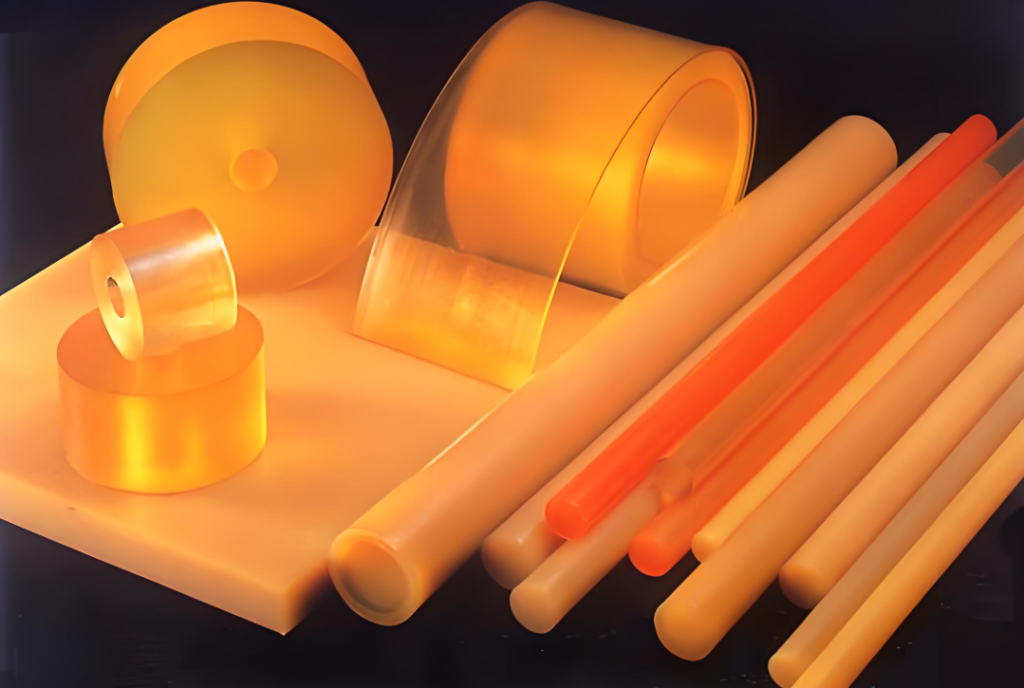

Customized structure optimization for space utilization: Polyurethane foam can be molded into structures such as "one-piece molded boxes" and "grooved pallets" through molding processes, which fit the shape of the goods (such as fruit and medicine packaging boxes) and reduce packaging gaps. After a certain pharmaceutical cold chain enterprise adopted polyurethane foam separation packaging, the number of vaccines that could be held in each box increased from 200 to 280, the space utilization rate rose by 40%, and the number of transportation vehicles decreased by 28%, indirectly lowering logistics costs.

Iii. Buffering and protective performance: Reduce the rate of goods damage and minimize transportation losses

Among cold chain goods, fresh produce (such as cherries and blueberries) and precision electronic components are prone to damage from vibration and impact. The elastic buffering property of polyurethane foam has become a key guarantee for transportation safety.

High elasticity for absorbing transportation shock: The compression rebound rate of polyurethane foam is over 85% (at a compression rate of 25%), effectively absorbing the energy generated by the jolting of trucks and the impact during loading and unloading. A comparative test at a certain cherry planting base shows that when cherries are packaged with a 5cm thick polyurethane foam buffer layer, the mechanical damage rate (skin damage and flesh bruise) after transportation drops from 25% to 6%, and the commercial rate increases by nearly 80%.

Puncture resistance and low-temperature resistance are suitable for complex transportation environments: In low-temperature conditions (-30℃), polyurethane foam still maintains good elasticity and shows no cracking, while EPS is prone to brittleness and damage below -20 ℃. In the cold chain transportation during northern winters, the damage rate of goods packaged with polyurethane foam is over 50% lower than that packaged with EPS, making it particularly suitable for long-distance transportation in severely cold regions such as Northeast and Northwest China.

4. Green and environmentally friendly features: Facilitating the low-carbon transformation of cold chain transportation and reducing environmental burdens

With the advancement of the "dual carbon" goals, the greenness of cold chain transportation is becoming increasingly important. The environmentally friendly characteristics of new polyurethane foam reduce the environmental impact of the transportation process throughout the entire packaging life cycle.

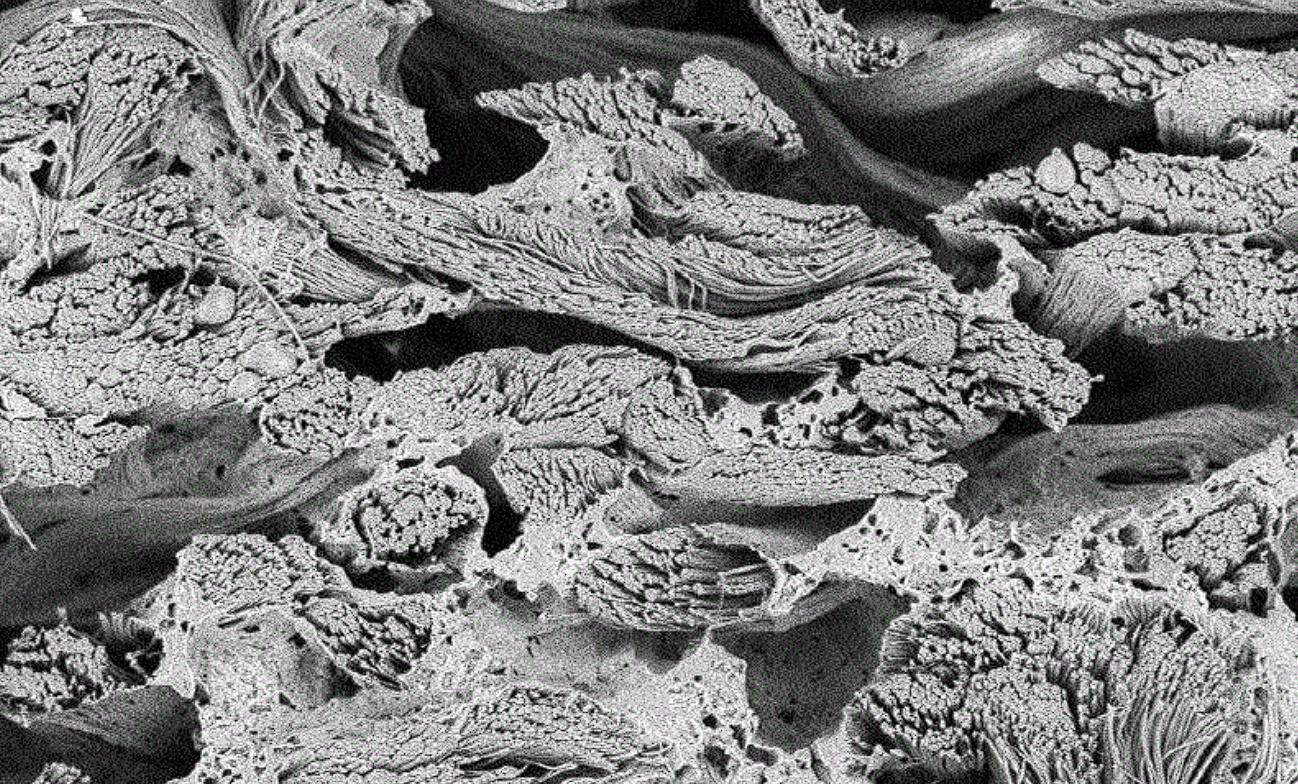

Recyclability reduces the pressure of waste disposal: Bio-based polyurethane foam (with bio-based components ≥30%) can be regenerated into buffer fillers through physical crushing or the raw materials can be recovered through chemical enzymatic depolymerization, with a recovery rate of over 90%. After a certain cold chain logistics enterprise established a polyurethane foam packaging recycling system, it reduced the annual landfill volume of packaging waste by 1,200 tons and lowered the cost of solid waste treatment by 600,000 yuan.

Low VOC emissions comply with green transportation standards Polyurethane foam that complies with CertiPUR-US® certification has a VOC emission of less than 0.5ppm, free of harmful substances such as formaldehyde and heavy metals. This prevents goods (such as food and medicine) from being contaminated by volatile substances from packaging during transportation, and at the same time reduces pollution to the interior of transportation vehicles, meeting the requirements of the EU's "Green Logistics" certification. Help enterprises expand their international cold chain transportation business.

Typical application cases: Efficiency Improvement in different transportation scenarios

Pharmaceutical cold chain (Road + Air) A certain vaccine enterprise adopts a combined packaging of "polyurethane foam insulated box + ice pack". During air transportation (with an ambient temperature ranging from -5 ℃ to 25℃), it can maintain a temperature of 2-8℃ inside the box for up to 96 hours, meeting the WHO PQS certification standards for international vaccine transportation. The transportation damage rate is controlled below 0.1%.

Fresh food cold chain (railway cold chain container) : A certain cold chain railway company laid a 50mm thick polyurethane foam insulation layer inside the container, combined with a temperature control system, making the temperature fluctuation inside the container ≤±1℃. The thawing loss rate of beef transported from Inner Mongolia to Guangzhou (48 hours) was reduced from 8% to 2%, achieving "zero spoilage throughout the cold chain".

Future development direction

Polyurethane foam cold chain packaging will be upgraded to "intelligent + efficient" : Firstly, it integrates temperature sensors to monitor the temperature inside the box in real time during transportation, and synchronizes it to the cloud through the Internet of Things to achieve abnormal temperature early warning. Second, develop "gradient density foam". According to the insulation and buffering requirements of different parts of the goods, design differentiated density structures to further reduce the weight by more than 15%. Third, promote the large-scale application of 100% bio-based polyurethane foam to further reduce carbon emissions throughout the packaging life cycle by 30%, and help cold chain transportation achieve the goals of "carbon peak and carbon neutrality".