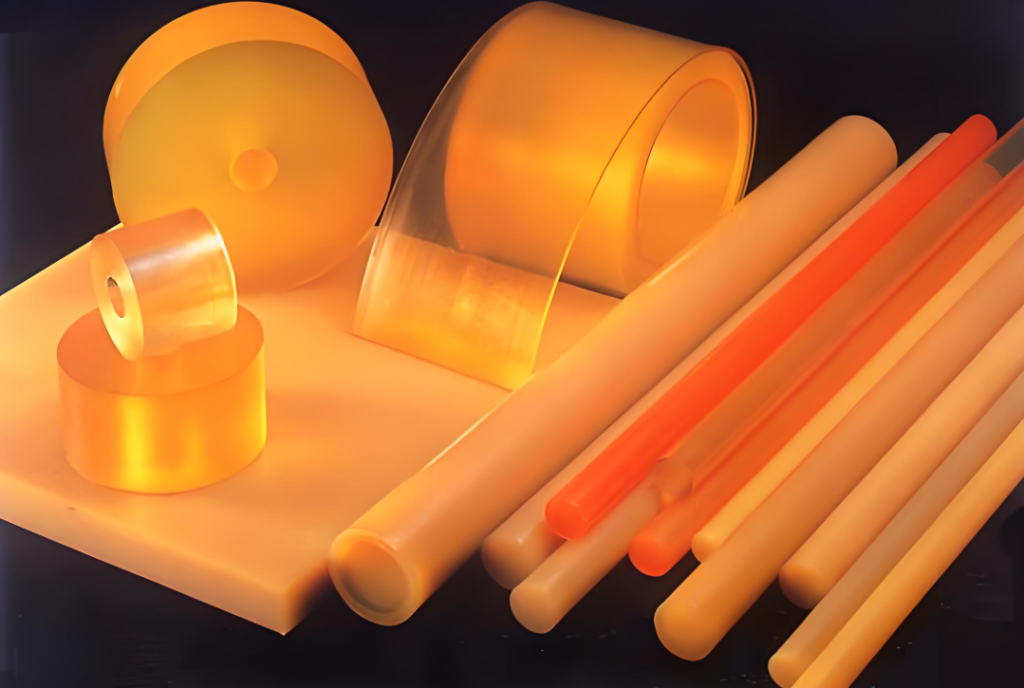

Polyurethane foam, as a fundamental material in furniture, automobiles, insulation and other fields, has long been confronted with environmental protection pain points such as "high-carbon raw materials, production pollution discharge and difficult disposal of waste" in traditional products. In recent years, with the substitution of bio-based raw materials, the upgrading of clean processes and breakthroughs in recycling technologies, new polyurethane foams have achieved a significant leap in environmental performance throughout their entire life cycle, establishing a green closed loop from the production end to the disposal end. The following is an analysis from the core dimensions.

I. Raw material end: Bio-based substitution and carbon footprint reduction

The new type of polyurethane foam, by replacing fossil raw materials with renewable resources, reduces environmental load from the source and has become a core path for carbon reduction.

The large-scale application of bio-based components: Huntsman's ACOUSTIFLEX®VEF BIO automotive acoustic foam uses bio-based polyols derived from vegetable oils, with a bio-based component ratio of up to 20%, reducing the carbon footprint by 25% compared to traditional products. This type of bio-based foam overcomes the shortcomings of early products, such as high VOC emissions and strong odors. Through a proprietary formula, it achieves low amine emissions and zero plasticizer addition, while maintaining lightweight and acoustic performance advantages.

Breakthrough in carbon dioxide-based raw materials: Some new types of foams are prepared from industrial by-product CO₂ to produce polyether polyols. Each 10,000 tons of foam can fix approximately 3,000 tons of CO₂, achieving "carbon fixation" production. The ozone depletion potential (ODP) of this type of foam is zero, completely avoiding the environmental risks of traditional fossil-based raw materials.

Ii. Production End: Clean processes and zero pollutant emissions

Through the innovation of foaming agents and process optimization in the production process, the source control of pollutants is achieved, which meets the requirements of green manufacturing.

Comprehensive replacement of environmentally friendly foaming agents: Traditional CFCs (chlorofluorocarbons) foaming agents have been completely banned due to their damage to the ozone layer. New foams generally adopt water-based foaming technology - using water in combined polyether to react with isocyanate to generate CO₂ as the foaming agent, with an ODP value of zero and no VOC emissions, while improving the open-cell property and dimensional stability of the foam. After a certain insulation foam enterprise adopted this technology, the production process reduced harmful gases by more than 90%.

Low-energy consumption molding technology: Huntsman's automotive foam system material, through formula optimization, has reduced the demolding time to 80 seconds, increasing production efficiency by 30% while lowering unit energy consumption. The popularization of continuous foaming production lines has reduced production energy consumption by 25% to 30% compared with intermittent processes, further cutting the carbon footprint in the production stage.

Iii. User End: Safety, low harm, Health and environmental protection Certification

The new type of foam has passed strict testing and certification to ensure that it is harmless to the human body and the environment during use, meeting the demands of high-end scenarios.

Strict control of harmful substances: Foam products that comply with CertiPUR-US® certification have established a complete safety standard system, explicitly prohibiting the use of ozone-depleting substances, PBDE flame retardants, heavy metals (lead, mercury), formaldehyde, and phthalates and other harmful components. Take memory foam for mattresses as an example. Its VOC emissions need to be less than 0.5ppm and can only be certified after a 72-hour adjustment test.

Health scene adaptation upgrade: The new medical foam adopts a low-sensitivity formula and has passed the ISO 10993 biocompatibility test, which can be directly used in medical mattresses and wound care excipients. Automotive foam, through aldehyde emission control technology, reduces aldehyde emissions to below 0.1mg/m³, meeting the EU in-vehicle air quality standards.

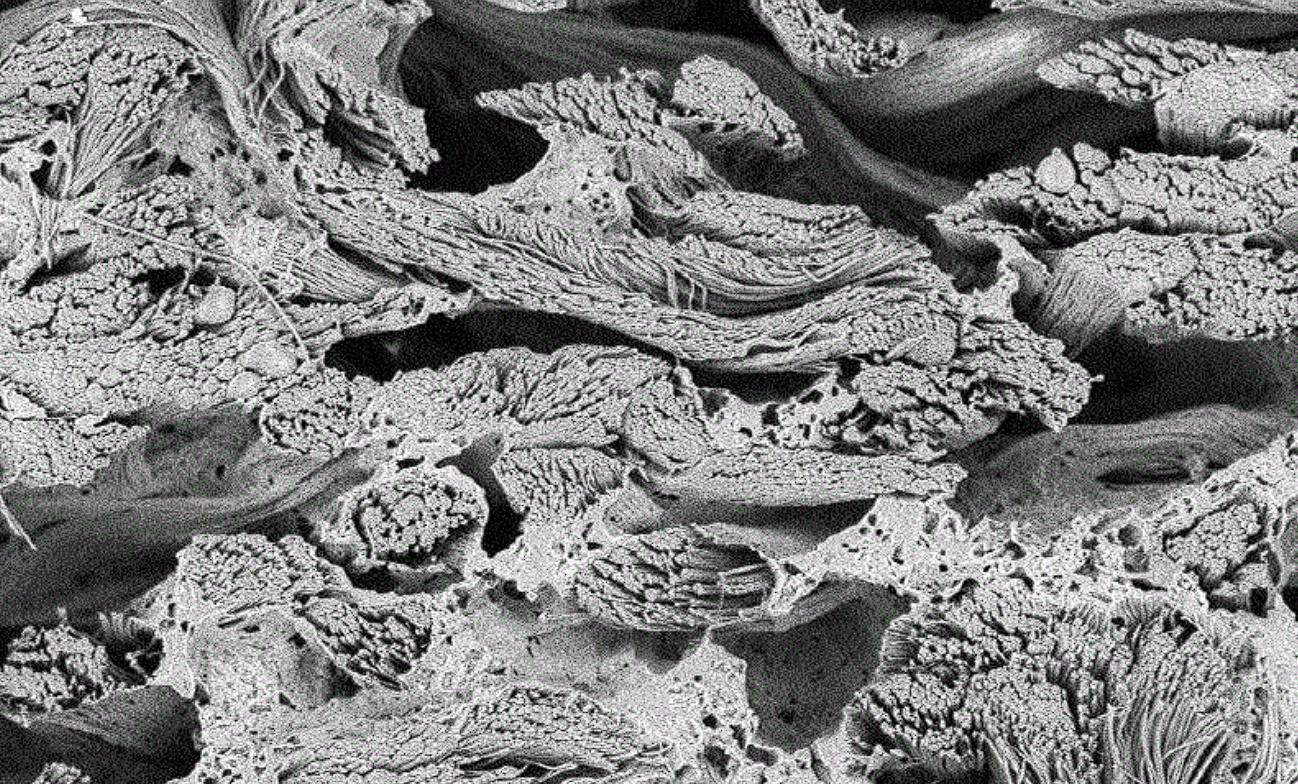

Iv. Waste End: Efficient recycling and resource recycling

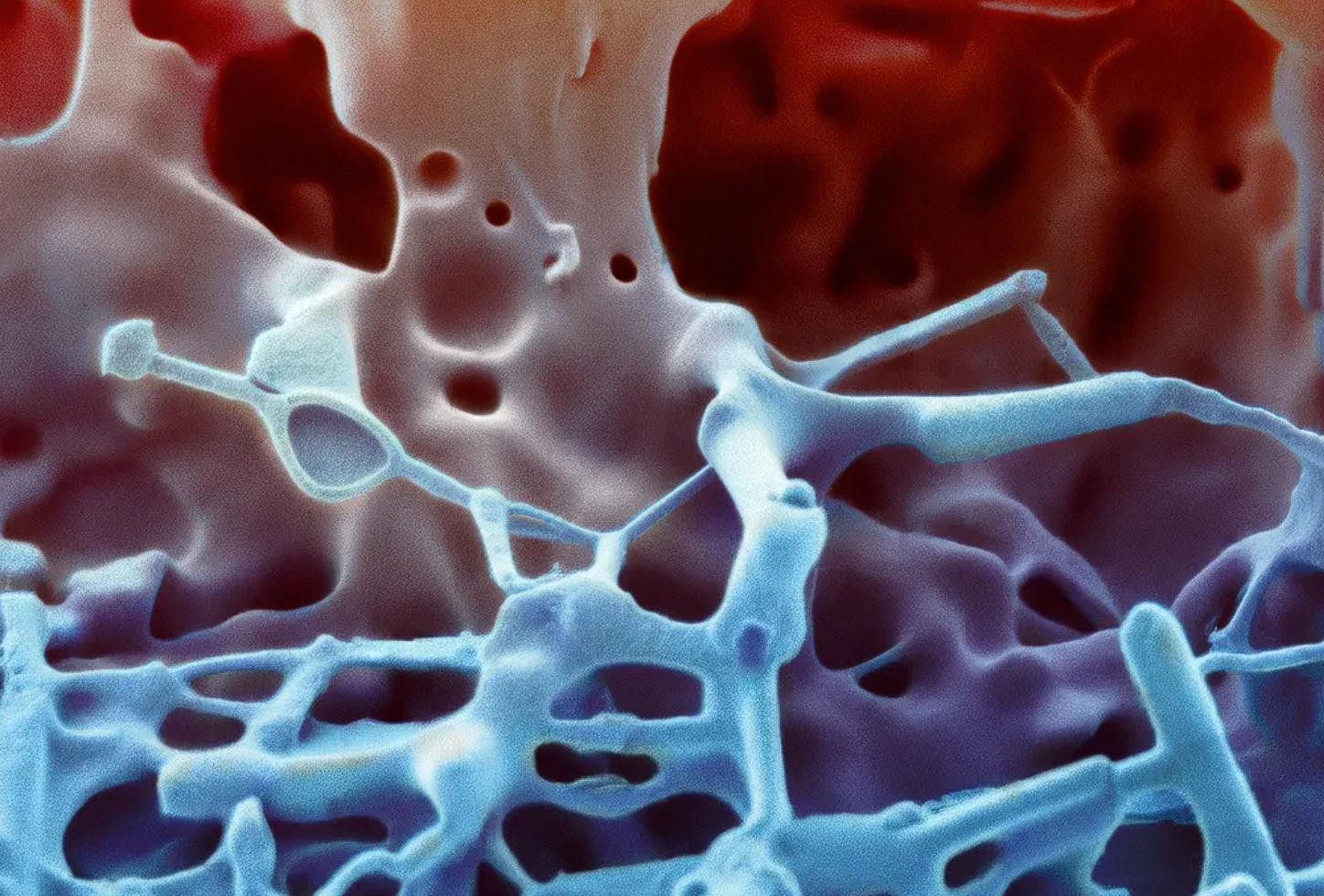

In response to the pain point of the difficult degradation of the cross-linked structure of polyurethane foam, recycling technologies such as chemical enzymatic methods have achieved efficient regeneration of waste resources.

Breakthrough in chemical enzymatic depolymerization: The ADPURase enzyme catalyst developed by Beijing University of Chemical Technology can achieve nearly complete depolymerization of kilogram commercial polyether foam (accounting for 75% of the foam market) within 8 hours, with a TDA monomer (isocyanate precursor) recovery rate of 94.7% and a diethylene glycol recovery rate of 98.5%. This technology has solved the problem that the bottom-phase products of traditional glycolysis become hazardous waste, enabling the foam to achieve a closed-loop cycle of "raw material - product - recycling - raw material".

High-value application of physical recycling: After being crushed and regenerated by hot melting, waste soft foam can be made into cushioning packaging materials or composite insulation boards, with a recycling rate of over 90%. A certain furniture enterprise has established a foam recycling system, processing 5,000 tons of waste foam annually and reducing landfill volume by 80%.

V. Environmental Protection Certification System and Industry Standards

International authoritative certifications have become an important endorsement for the environmental performance of new foam, promoting the standardized development of the industry.

Certification system

Core environmental protection indicators

Applicable scenarios

CertiPUR-US®

VOC < 0.5ppm, six types of harmful substances are prohibited

Mattresses, furniture, cushioning materials

Eco-label (EU

The bio-based content is ≥15%, and the recycling rate is ≥80%

Building insulation, automotive interiors

Blue Angel (Germany)

Production energy consumption is reduced by 20%, and there is no heavy metal emission

Foam products for household and industrial use

Future development direction

The environmental performance of the new type of polyurethane foam will be upgraded towards "extreme greenness throughout the entire chain" : the proportion of bio-based components is expected to exceed 50%, achieving large-scale production of 100% bio-based foam. Chemical enzymatic recovery will be deeply integrated with the production process to establish a "production and collection" circular factory. The intelligent responsive foam can automatically decompose after the end of its service life through a degradation trigger mechanism, completely solving the problem of disposal. With the tightening of environmental protection regulations and technological iterations, polyurethane foam will become a benchmark material that combines performance advantages with environmental friendliness.